Narrow web printing thrives on precision. Every component in the production chain must align – substrates, inks, press speeds, curing methods. Traditional mercury-vapor UV systems once dominated this space, but LED curing technology now redefines efficiency for label converters and packaging specialists. Let’s examine why shops running flexo, offset, or hybrid presses increasingly choose LED-powered solutions.

Energy consumption drops immediately with LED adoption. Unlike mercury lamps requiring 20-30 minutes of warm-up, LED arrays activate at full intensity within microseconds. This eliminates idle energy drain during press stoppages – a critical factor in job changeovers common in short-run label production. Operators report 60-70% reductions in power bills after switching, with no compromise in cure quality. The directional nature of LED output further minimizes heat generation, preventing substrate distortion on temperature-sensitive materials like thin-gauge films or pressure-sensitive labels.

Print speed optimization separates profit-makers from break-even operations. LED systems achieve instant-on/off capabilities that synchronize perfectly with press start/stop cycles. There’s no lamp degradation over time – consistent UV output maintains cure reliability at maximum press speeds throughout the LED’s 20,000 hour lifespan. For flexographic printers running alcohol inks on porous stocks, this stability prevents costly varnish curing defects during long runs. Offset shops benefit from tighter control over oxidation processes when curing hybrid UV/conventional inks.

Material compatibility expands with LED’s cooler operation. Cold-cure capabilities allow printing on heat-sensitive substrates previously deemed unsuitable for UV processes – think thin PET bottles, thermal transfer ribbons, or foam-core materials. Specialty applications like tamper-evident labels with fragile destruct features gain new production possibilities. LED’s narrow wavelength spectrum (typically 365-395nm) also enables formulation of photoinitiator-specific inks that cure without affecting adjacent colors – a game-changer for high-density gamut printing.

Maintenance costs plummet when mercury lamps exit the equation. No more quarterly bulb replacements, reflector cleanings, or hazardous waste disposal protocols. LED systems operate without ozone generation, eliminating the need for exhaust ventilation retrofits. Dust-sensitive environments like medical label production see reduced contamination risks from air movement. The solid-state design withstands vibration better than fragile quartz lamps, crucial for presses with reciprocating parts.

Environmental compliance becomes simpler. Mercury-free technology aligns with RoHS directives and sustainability reporting requirements. Printers eliminate toxic lamp disposal costs while reducing carbon footprint through energy savings. Water-washable LED UV inks gain traction as shops phase out solvent-based cleaning systems. This transition proves particularly valuable for brands requiring ISO 14001 certification or targeting eco-conscious markets.

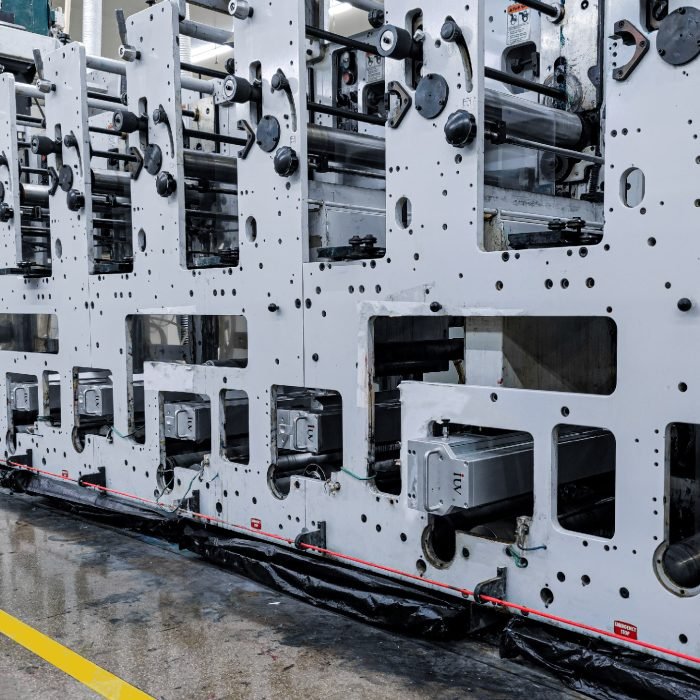

Process integration flexibility sets LED apart. Modular arrays adapt to irregular web paths common in multi-process presses. Shrink sleeve converters benefit from 360-degree curing configurations impossible with conventional UV tunnels. Hybrid systems allow mixing LED with other curing methods – a growing trend among printers handling diverse jobs. Post-cure yellowing concerns disappear with optimized wavelength matching, critical for premium cosmetic labels requiring perfect whites.

Ink chemistry innovations accelerate alongside LED adoption. Formulators now create low-migration inks cured at 20% less energy than first-generation UV materials. Food-safe packaging printers leverage this advancement to meet stringent FDA guidelines without sacrificing production speed. Metallic pigment suspensions achieve higher brilliance through tailored cure profiles that prevent heat-induced oxidation.

The operational calculus proves clear for narrow web specialists. Reduced energy bills, faster job turnarounds, expanded substrate options, and regulatory compliance form a compelling ROI narrative. As LED emitter costs continue declining while output intensities rise, the technology transitions from premium option to operational necessity. Forward-thinking shops already position this upgrade as part of broader digital transformation strategies – integrating with color management systems and IoT-enabled press controls. Those delaying adoption risk ceding ground to competitors wielding faster, cleaner, and more adaptable production capabilities.