The hum of a printing press accelerates as another label order queues up. Across the industry, converters face the same dilemma – how to cure UV inks fast enough without melting heat-sensitive materials. Traditional mercury vapor lamps have long dictated this dance, their infrared radiation warping thin films and forcing press speeds below capacity. Enter LED curing systems, rewriting the rules of energy deployment in narrow web printing.

Unlike their predecessors, LED UV units emit minimal infrared radiation – 75% less heat according to recent pressroom trials. This thermal precision proves critical when printing on PET labels for cold beverage containers or temperature-sensitive pharmaceutical packaging. The physics are straightforward: LEDs activate photoinitiators in UV inks through specific wavelengths (typically 365-405nm), bypassing the broad-spectrum approach that wastes energy as heat.

Flexographic printers running short runs of premium wine labels report 40% faster job turnover since switching to LED. The elimination of lamp warm-up periods allows instant curing on demand. One Midwest converter serving craft breweries reduced their substrate waste from 3.2% to 0.7% annually by eliminating heat-induced material distortion during curing.

Offset printers adopting hybrid curing systems observe unexpected benefits. The cool operation preserves delicate ink film formations on coated stocks, maintaining dot integrity for high-line screen work. A New Jersey printer specializing in cosmetic packaging achieved 98% first-pass yield on metallized substrates after retrofitting their 6-color press with LED interdeck units.

Energy consumption metrics tell their own story. Where conventional UV systems draw 80-120 watts per centimeter, LED arrays operate at 12-18W/cm. A European study tracking 23 label converters found average energy savings of 68% post-LED adoption. Maintenance costs nosedive too – no mercury lamps to replace every 1,000 hours, no reflector degradation from heat cycling.

The chemistry behind LED-curable inks has matured dramatically. Major ink manufacturers now offer formulations with photoinitiators tuned to specific LED wavelengths. This spectral alignment achieves full curing at speeds exceeding 200m/min, with some UV flexo inks reaching 95% cure conversion in 0.15 seconds. Printers report better ink adhesion on polyolefin films previously prone to delamination.

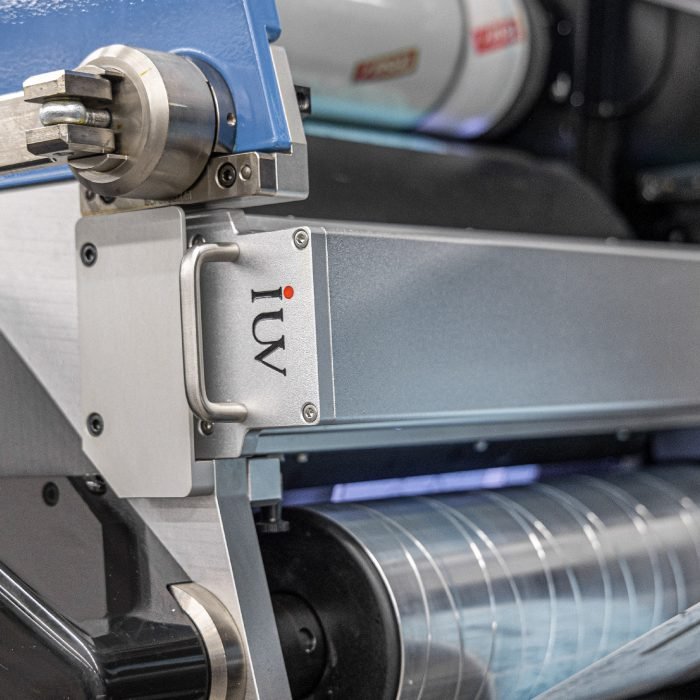

Press configurations adapt seamlessly. Retrofit kits for legacy equipment typically integrate within existing drying sections, while new presses increasingly feature modular LED arrays. The latest hybrid systems allow operators to blend LED and conventional UV output, useful for curing thick white undercoats followed by detailed graphics.

Environmental factors accelerate adoption. Mercury-based systems face increasing regulatory scrutiny, while LEDs contain no hazardous materials. The elimination of ozone generation removes the need for costly ventilation systems – a key advantage in urban print facilities.

Substrate compatibility continues expanding. Early concerns about curing opaque materials have been addressed through dual-wavelength LED systems. One manufacturer’s 395nm 365nm configuration successfully cures inks beneath aluminum foil layers in pharmaceutical blister packaging.

As print buyers demand shorter runs and faster turnarounds, LED curing’s instant-on capability becomes strategic. The technology enables profitable micro-runs – a game-changer for private-label producers and seasonal promotions. Pressrooms once constrained by heat accumulation can now stack jobs back-to-back without cooling delays.

The productivity math convinces skeptics. A typical 8-hour shift gains 47 minutes of additional press time through eliminated warm-up cycles. Over a year, that’s 285 extra production hours. Combine this with reduced waste and energy costs, and the ROI window shrinks to 14-18 months for most mid-sized operations.

Looking ahead, wavelength-specific LEDs promise to unlock new applications. 385nm systems show potential for curing through certain colored films, while research continues into UV-LED activated adhesives for inline label applications. As material science advances, the synergy between LED curing and next-gen substrates will likely redefine print capabilities across packaging verticals.

For converters weighing the transition, the question shifts from “if” to “when”. With major OEMs now offering LED options across their press portfolios, and ink chemistry keeping pace, the infrastructure for widespread adoption exists. Those who leverage this thermal precision will likely find themselves printing tomorrow’s labels on today’s presses.