UV curing systems have quietly transformed packaging production floors by solving a fundamental challenge – how to print on increasingly diverse materials without compromising speed or quality. As brands demand eye-catching metallized films, heat-sensitive plastics, and unconventional sustainable substrates, traditional drying methods hit physical limitations. The science behind UV curing’s material versatility lies in its photochemical precision.

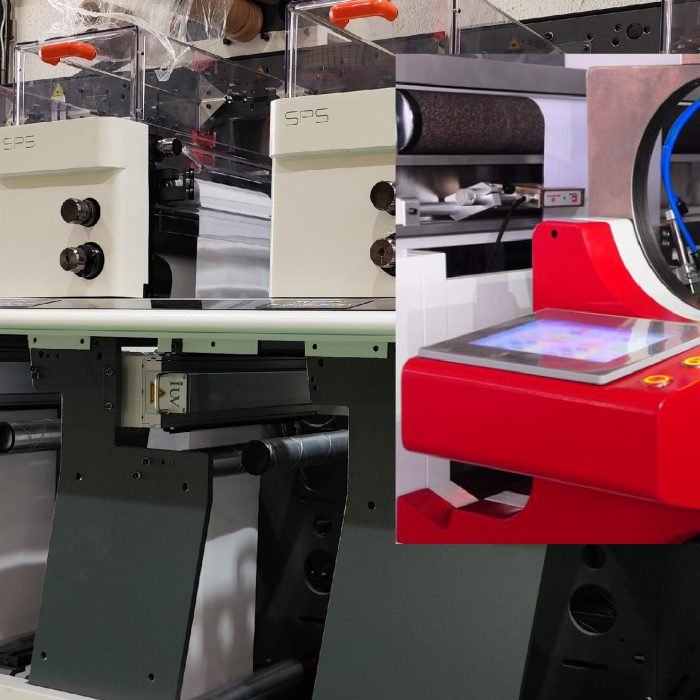

In label printing operations, UV technology enables presses to handle everything from PET shrink sleeves to textured synthetic papers. Unlike solvent-based inks that require porous surfaces, UV formulations cure through immediate polymerization when exposed to specific light wavelengths. This instant solidification prevents ink absorption issues on non-porous stock like BOPP films or metallicized labels. Flexo printers particularly benefit when running sensitive substrates – UV curing eliminates heat distortion in thin-gauge polypropylenes during inline processes.

Sheet-fed offset applications reveal another dimension of substrate flexibility. Hybrid UV systems allow printers to switch between conventional and UV inks without extensive wash-ups, making coated cardboard, acrylics, and even some recycled materials viable options. The controlled curing environment prevents warping in heavyweight packaging boards that would normally curl under IR drying tunnels.

Narrow web converters face unique material challenges when producing flexible packaging or tamper-evident seals. LED-UV systems address this through adjustable spectral output – technicians can fine-tune wavelengths between 365-395nm to match photoinitiators in specialty inks. This spectral targeting proves critical when printing on temperature-sensitive materials like PVC or low-surface-energy plastics that repel conventional coatings.

Three material science principles drive UV’s compatibility advantages. First, the absence of solvent evaporation removes shrinkage forces that delaminate multilayer substrates. Second, instant curing creates a chemical bond rather than mechanical adhesion, improving ink anchorage on challenging surfaces. Third, UV systems enable lower ink film thicknesses while maintaining opacity, reducing the physical stress on delicate stocks.

Operational impacts become tangible in finishing stages. UV-cured prints withstand die-cutting, foil stamping, and embossing immediately after curing, eliminating traditional drying delays. This proves invaluable for composite packaging materials requiring multiple decoration steps. The cured ink’s cross-linked polymer structure also enhances abrasion resistance – a critical factor for cosmetic packaging or industrial labels facing harsh transport conditions.

Energy dynamics play an underappreciated role in material compatibility. LED-UV systems generate minimal radiant heat compared to mercury-vapor lamps, protecting heat-sensitive stocks like polystyrene or thin-gauge metallized films. This thermal management allows printers to experiment with novel biodegradable substrates that couldn’t withstand conventional drying temperatures.

The environmental angle further expands substrate options. UV curing facilitates alcohol-free printing and eliminates VOC emissions, meeting sustainability requirements for packaging destined for eco-conscious markets. This chemical profile compatibility enables printers to use recycled papers and plant-based films that react poorly to solvent-based inks.

As packaging designers push material boundaries, UV curing systems evolve in tandem. Recent advancements in dual-cure chemistry allow partial curing for intermediate steps in complex folding carton production. Adjustable intensity controls enable printers to dial in exact energy levels for sensitive materials like thermal transfer ribbons or conductive inks.

The true measure of this technology lies in its silent enablement of packaging innovation – from resealable medical pouches to textured luxury boxes. By removing historical constraints between ink chemistry and substrate physics, UV curing systems have become the unspoken enabler of tomorrow’s packaging landscape.