Substrate choice directly shapes the final quality of printed labels, acting as the foundation that interacts with every element of the printing process. In label production environments – whether flexographic, offset, or narrow web operations – material selection impacts ink adhesion, color fidelity, and durability. Modern LED UV curing systems add another layer of complexity, requiring substrates that respond optimally to specific wavelengths and energy outputs.

Paper substrates remain popular for wine labels and premium products, with uncoated varieties absorbing more ink while coated stocks enable sharper dot reproduction. The porosity of paper affects drying times significantly in conventional printing, though LED UV systems mitigate this through instant curing. Film materials like BOPP and PET dominate pressure-sensitive labels, demanding precise surface tension levels (ideally 38-42 dynes/cm) to prevent ink crawling. Polyethylene films often require corona treatment before printing to achieve necessary adhesion.

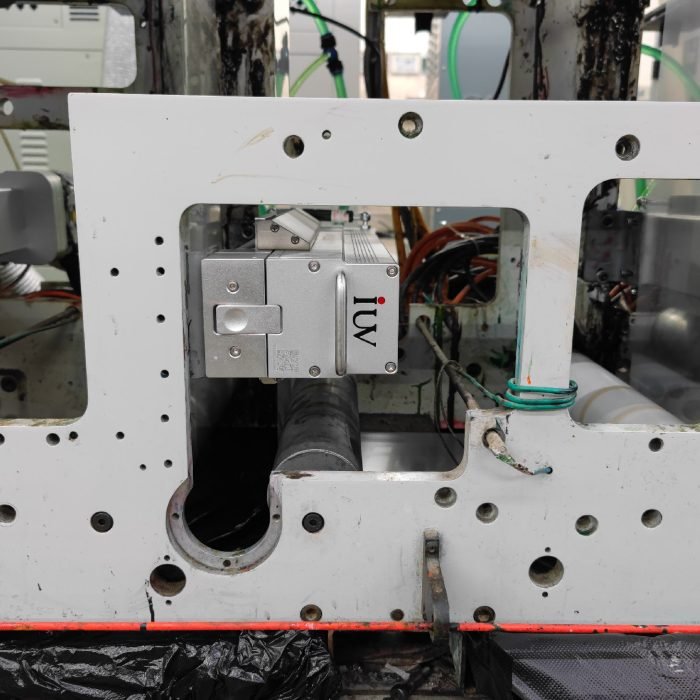

Metallized substrates present unique challenges with their reflective surfaces. Silver holographic stocks can cause color shift phenomena, requiring press operators to adjust ink densities by 15-20% compared to standard materials. LED UV curing proves particularly effective here, as its cold cure process prevents foil delamination risks associated with heat-based drying systems.

Textile labels introduce different parameters, where material flexibility and wash resistance take priority. Screen-printed textile tags benefit from UV-curable inks that cure into flexible films, maintaining adhesion through repeated industrial laundering. The substrate’s stretch capability must match the ink’s elongation properties – a mismatch causes cracking during garment stretching.

Environmental factors increasingly influence substrate selection. Compostable films like PLA require modified ink formulations with lower viscosity to penetrate the biodegradable surface layer effectively. LED UV systems support these eco-friendly initiatives through energy efficiency gains of 60-70% compared to traditional mercury vapor lamps, while eliminating ozone emissions.

Surface texture plays an underappreciated role in print quality. Embossed papers can distort fine text below 4pt, while smooth synthetic stocks enable reproduction of microtext security features. Rough surfaces demand higher ink film thickness – sometimes requiring multiple hits in flexo printing – which impacts production speed and material costs.

Thermal stability becomes crucial in applications like automotive labels. Engine compartment tags must withstand 150°C temperatures without substrate warping that would distort printed information. Polyimide films paired with UV-curable inks meet these demands, maintaining dimensional stability where standard PET would fail.

Moisture resistance requirements vary dramatically between applications. Bath product labels need 100% waterproof substrates, while frozen food packaging must resist condensation-induced label lifting. UV-cured inks on synthetic stocks create impervious seals, though improper curing can leave microscopic pores that compromise moisture resistance.

Opacity requirements dictate substrate thickness and composition. White BOPP films at 50μm thickness provide sufficient opacity for most applications, but translucent products like essential oil bottles often use clear films with reverse-printed designs. This technique leverages the substrate’s clarity while protecting the printed image from abrasion.

Electrical properties matter in RFID label production. The substrate’s dielectric constant affects antenna performance, requiring materials with consistent electrical characteristics across production batches. UV curing assists here by preventing heat-induced dimensional changes that could alter antenna geometry during printing.

Cost considerations always factor into substrate selection. While premium materials enhance perceived value, lean manufacturing principles push for the thinnest possible substrates that meet performance requirements. A 10μm reduction in film thickness can yield annual material savings exceeding $100,000 in high-volume operations, without compromising print quality when using precision coating systems.

The interaction between substrate and ink chemistry remains critical. Solvent-based inks penetrate porous materials differently than UV-curable formulations. Newer hybrid inks combine technologies, allowing partial penetration before UV curing creates a protective surface layer. This approach marries the durability of UV curing with the substrate adhesion benefits of traditional ink systems.

Label converters must balance these technical considerations with aesthetic goals. The tactile experience of a label – whether velvety soft-touch coatings or crisp metallic finishes – starts with substrate selection. Brushed metal effects can be achieved through actual metalized films or sophisticated printing techniques on standard stocks, each choice carrying different cost and durability implications.

As digital printing gains market share, substrate compatibility becomes more complex. Electrophotographic systems require materials with precise conductivity levels, while inkjet technologies need controlled absorption rates. The common thread across all technologies remains – successful label printing starts with understanding how ink, process, and substrate interact at fundamental physical and chemical levels.