The hum of machinery in a print shop tells a story older than Guttenberg’s press, but today’s chapters read differently. LED UV curing flexo printing isn’t just another technical upgrade—it’s rewriting production narratives for label converters, packaging specialists, and narrow-web printers. Let’s cut through the industry noise to examine why this fusion of light-emitting diodes and flexographic processes is making litho veterans rethink their playbooks.

Traditional mercury-vapor UV systems dominated curing for decades, but their operational reality reads like a list of compromises. Heat generation warps thin substrates. Ozone emissions require industrial ventilation. Energy consumption spikes during idle periods. Enter LED UV—a spectral shift from broad-spectrum bulbs to targeted wavelengths. The 365-405nm sweet spot activates photoinitiators without the infrared baggage, turning curing into a cold process. Printers running pressure-sensitive labels now clock 20-30% faster line speeds simply by eliminating heat-related substrate distortion.

Flexo’s inherent strength—versatility across substrates—gets amplified under LED UV. Filmic materials prone to curling under conventional UV? They lie flat. Heat-sensitive shrink sleeves retain dimensional stability. The absence of thermal stress means printers can transition between paper stocks and synthetic films without recalibrating drying parameters. One converter reported a 47% reduction in waste when switching PET label jobs to LED-cured flexo.

Narrow-web operators see particular advantages in quick turnaround environments. Instant on/off capability slashes energy use during job changes—no more idling lamps between runs. A Midwest label house trimmed their monthly power bill by 18% post-LED retrofit while maintaining 24/5 production schedules. Mercury systems’ warm-up times become irrelevant when curing modules activate at the press of a button.

Ink chemistry plays co-star in this production shift. LED-specific formulations leverage narrower photoinitiator bands, achieving full cure at lower energy thresholds. One major ink supplier’s data shows 75% less initiator content compared to conventional UV flexo inks, reducing odor and potential migration—critical for food-contact packaging. Print opacity remains consistent even with thinner ink films, a cost-saving side effect material managers appreciate.

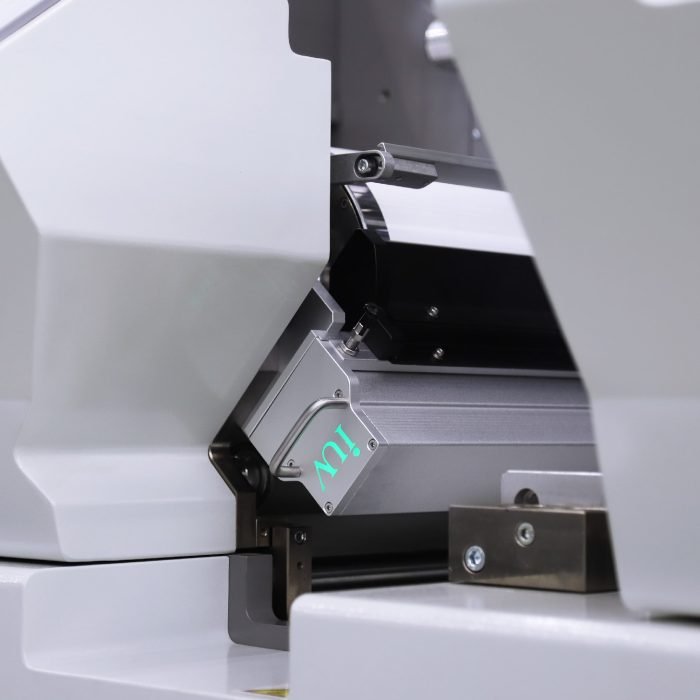

Press configurations adapt to the LED advantage. Shorter curing units allow for more print stations within existing press footprints. One European converter added white ink and varnish capabilities to their 8-color flexo press simply by retrofitting LED modules. The cooler process enables tighter web paths too—a boon for delicate substrates like unsupported films.

Durability metrics surprise even seasoned press operators. Abrasion resistance tests on LED-cured polypropylene labels show 2-3x improvement over thermal-cured counterparts. The secret lies in complete polymerization; without heat-induced surface curing, ink layers crosslink uniformly. Scuff-resistant pharmaceutical labels now survive automated bottling lines that previously required laminated constructions.

Environmental math makes CFOs take notice. LED systems consume 60-70% less energy than mercury vapor units. Factor in eliminated exhaust systems and reduced HVAC loads, and the carbon footprint shrinks dramatically. A West Coast printer achieved ISO 14001 certification within six months of full LED adoption—their mercury lamp disposal costs dropped to zero overnight.

But let’s ground this in pressroom reality. Job changeovers accelerate when curing parameters stay consistent across substrates. Operators report 15-minute makereadies for jobs that previously required 45 minutes of lamp adjustments. Color matching benefits from stable curing intensities—no more chasing viscosity changes caused by heat fluctuations.

The sustainability story extends beyond energy stats. LED modules last 20,000 hours versus 1,000-2,000 for mercury bulbs. One converter calculated they prevented 1.3 tons of hazardous waste over three years through eliminated bulb replacements. Combine this with VOC-free inks, and LED UV flexo becomes a cornerstone for eco-conscious packaging.

Press manufacturers are rethinking component layouts. Newer flexo models position LED arrays closer to the print station, slashing web travel between impression and cure. This proximity reduces dot gain variation—critical for high-line screen process work. One luxury brand’s metallic ink job saw dot fidelity improvements that halved their approval proofs.

For converters straddling flexo and digital print, LED curing bridges the gap. Hybrid configurations now allow UV inkjet units to inline with flexo stations, all cured under unified LED arrays. A label printer serving craft breweries combines flexo metallics with variable digital text, cured simultaneously at 150m/min. The operational simplicity defies traditional hybrid press complexity.

Maintenance logs tell their own tale. No more quartz sleeve replacements or reflector cleanings. LED arrays withstand the vibration that plagued filament-based systems. Downtime for curing-related issues dropped 90% in multiple case studies. Technicians now spend minutes monthly on light maintenance versus hours weekly with legacy UV systems.

As substrate innovation accelerates, LED UV flexo keeps pace. Printed electronics on PET films? Check. Conductive inks for smart packaging? Achievable. The cold cure process preserves material properties that heat would compromise. Researchers recently demonstrated RFID antenna printing directly onto temperature-sensitive bioplastics—a feat possible only with LED curing.

The economic argument solidifies when examining total cost per meter. While LED modules carry higher upfront costs, the ROI timeline shrinks with energy savings, reduced waste, and productivity gains. A label converter’s analysis showed 14-month payback period transitioning two flexo presses—faster than their three-year projection.

In pressrooms worldwide, the evidence mounts through quieter exhaust systems, cooler substrates, and fewer rejected rolls. LED UV curing in flexo printing isn’t just an alternative—it’s becoming the new baseline for competitive converters. As material scientists push substrate boundaries and ink chemists refine formulations, this technology partnership keeps delivering cleaner prints, cooler operations, and leaner production flows. The future of flexographic printing glows with precise, energy-efficient light—no mercury required.