Switching to LED UV offset printing isn’t just another equipment upgrade—it’s a strategic pivot with measurable financial upside. For operations running label presses, flexo jobs, or narrow-web setups, the shift unlocks efficiency gains that ripple across production floors. Let’s break down how this technology transforms workflows while padding your bottom line.

Traditional UV systems rely on mercury-vapor lamps that guzzle energy and demand frequent bulb replacements. LED UV curing flips that script. These solid-state units consume 70% less power on average, slashing electricity bills from day one. Unlike conventional setups requiring warm-up time, LEDs hit full intensity instantly—no waiting for lamps to stabilize between jobs. That idle time adds up: a mid-sized shop running two shifts could reclaim 300 hours annually just by eliminating lamp warm-up cycles.

Drying speed becomes a competitive weapon with LED UV. Water-based inks and coatings cure near-instantly under specific wavelengths, letting presses ramp to full speed without fear of smudging. For label converters handling wine bottles or cosmetic packaging, this means tackling metallic inks and delicate substrates that previously required secondary drying tunnels. Jobs that used to bottleneck at the curing stage now flow through single-pass.

The environmental angle isn’t just PR fluff. Mercury-free LED systems eliminate hazardous waste disposal costs tied to traditional UV lamps. Facility managers report 40-60% reductions in HVAC load since LED units don’t blast excess heat into production areas. In climate-controlled warehouses, that translates to lower cooling costs year-round.

Substrate flexibility quietly drives ROI. LED UV’s cooler operation lets printers work with heat-sensitive materials like thin films and pressure-sensitive labels that warp under conventional drying. Packaging clients increasingly demand hybrid jobs—think folding cartons with tactile textures next to metallic accents. LED handles these in-line without retrofitting.

Downtime takes a haircut too. With no bulbs to replace and minimal maintenance, LED systems keep presses rolling. A label shop in Ohio tracked a 17% uptick in monthly output post-conversion simply from avoiding lamp-related stoppages. Faster job turnarounds mean more capacity to take on rush orders at premium rates.

Energy savings get attention, but material optimization is the stealth profit booster. LED-cured inks remain stable on press longer, reducing washup frequency between color changes. One commercial printer cut ink waste by 22% in the first quarter after switching—equivalent to $18,000 annualized savings on consumables alone.

The health component matters for talent retention. Traditional UV setups require extensive ventilation to handle ozone byproducts. LED systems generate negligible ozone, creating cleaner air for press operators. Fewer respiratory complaints mean lower absenteeism and insurance premiums—a secondary cost squeeze many overlook.

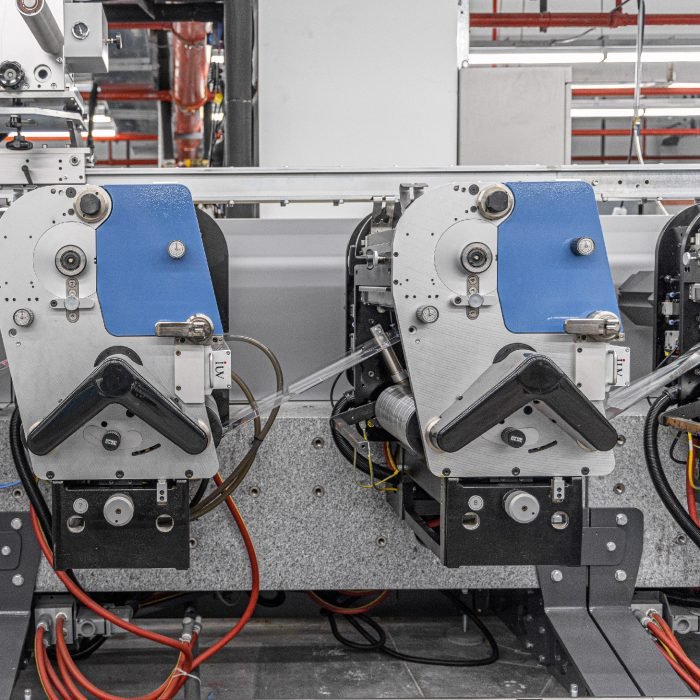

For commercial printers juggling mixed workflows, LED UV’s compatibility with existing offset infrastructure smooths the transition. Retrofitting a 40-inch press typically takes under a week, with most operations recouping costs within 18 months through energy and consumable savings. The math gets compelling at scale: a plant running 10 presses could see seven-figure annual savings by migrating the entire fleet.

Niche applications amplify returns. Security printers using fluorescent inks gain precision control over curing, reducing defect rates on banknote threads. Pharma packagers leverage LED’s instant on/off capability for short-run serialization jobs without energy penalties. Even commercial shops doing variable-data work benefit—UV coatings cure uniformly regardless of sheet content, eliminating reprints from coating defects.

Skeptics fixate on upfront costs but miss the bigger picture. Modern LED modules last 20,000 hours—about a decade of normal use. Factor in tax incentives for energy-efficient upgrades in many regions, and the payback window shrinks further. Leasing options with bundled maintenance make the switch cash-flow positive from month one for smaller operations.

The market’s shifting beneath our feet. Brands now audit suppliers’ sustainability practices, with LED UV adoption becoming a differentiator in RFQ processes. Printers clinging to old systems risk becoming cost uncompetitive as clients demand shorter runs with zero VOC emissions. Those who’ve already transitioned report higher client retention rates and expanded margins on specialty work.

This isn’t future talk—it’s today’s balance sheet reality. The shops thriving now are those who treated LED UV not as a discretionary upgrade but as operational necessity. They’re the ones quoting tighter turnarounds, winning contracts against digital-only rivals, and reinvesting savings into next-gen capabilities. The question isn’t whether to switch, but how fast your operation can retool to leave competitors curing under yesterday’s lamps.