Absolutely! Let’s dive into the world of UV Curing Flexo Printing for Labels. I’ll craft a piece that’s informative, engaging, and optimized for search engines, all while keeping those technical details sharp and accessible.

UV Curing Flexo Printing for Labels: Benefits and Best Practices

Flexographic printing, often called flexo, is a powerhouse in the label printing industry. It’s a versatile method that uses flexible relief plates to transfer ink. For narrow web label printing, flexo is king. It excels at high-speed, high-volume production runs. Now, imagine combining this with UV curing technology. This is where UV curing flexo printing for labels truly shines.

UV curing uses ultraviolet light to instantly dry or “cure” inks, coatings, and adhesives. This process is incredibly fast. It happens in a fraction of a second. Traditional drying methods can be slow. They might involve heat or evaporation. UV curing, on the other hand, solidifies the ink immediately. This offers a host of advantages for label printers.

One of the biggest benefits is enhanced durability. UV-cured inks form a tough, scratch-resistant surface. This is vital for labels that endure handling, abrasion, or exposure to the elements. Think of product labels on cleaning supplies or automotive parts. They need to look good and stay legible over time. UV curing provides that resilience.

Speed is another major win. Because the ink cures instantly, labels can move through the printing process without waiting for drying. This significantly boosts production speeds. Presses can run faster. More jobs can be completed in less time. This translates directly into increased efficiency and profitability for label manufacturers.

Environmental advantages are also noteworthy. UV inks are typically 100% solids. This means they contain very few or no volatile organic compounds (VOCs). VOCs are harmful chemicals that evaporate into the air. Reducing VOC emissions is a major goal for many printing operations. UV curing helps achieve this. It also means less waste.

The quality of print with UV curing flexo is exceptional. UV inks offer vibrant colors and sharp, defined details. They adhere well to a wide range of substrates. This includes paper, films, and foils. The instant curing locks the ink onto the surface. This prevents smudging and bleeding, ensuring crisp graphics and text.

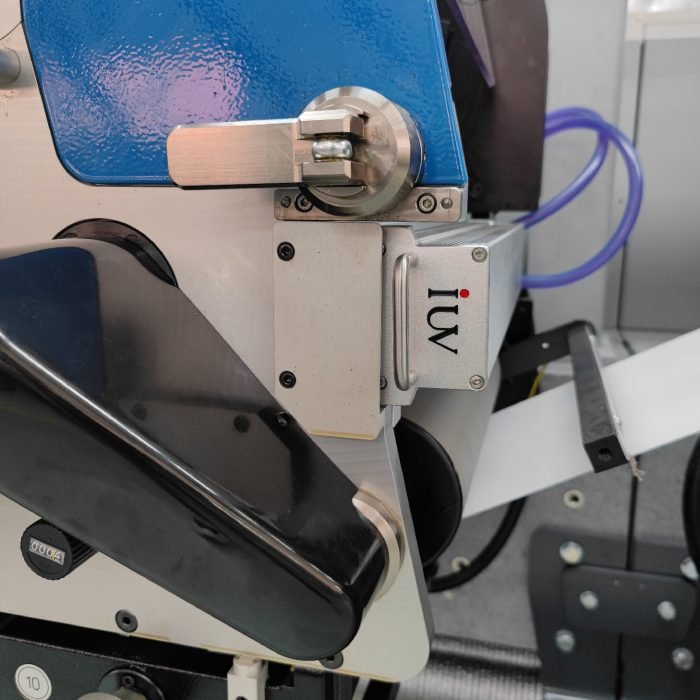

LED UV curing technology takes these benefits even further. Traditional UV curing used mercury vapor lamps. These lamps generate significant heat and consume more energy. They also have a shorter lifespan. LED UV lamps are different. They are more energy-efficient. They produce less heat. Their lifespan is much longer. This reduces operational costs and maintenance.

LED UV systems also offer more consistent curing. They deliver a focused spectrum of UV light. This ensures reliable curing across the entire print width. They can also be switched on and off instantly. This saves energy when the press is stopped. It also prevents premature curing of inks on the rollers.

When implementing UV curing flexo printing, several best practices are key. First, substrate compatibility is crucial. Not all substrates react the same way to UV inks. Test different materials to ensure proper adhesion and curing. Some films might require surface treatment for optimal results.

Ink formulation is another area to consider. UV inks are specialized. They are designed to cure under UV light. Ensure you are using high-quality UV inks that match your press and substrate. Different ink types exist, such as conventional UV, low-migration UV, and LED UV inks. Choosing the right type depends on the application. For food packaging, low-migration inks are essential to prevent any potential contamination.

Press setup and maintenance are vital. Proper anilox roll selection ensures correct ink transfer. The correct plate mounting is also important for image quality. Keep your UV lamps clean and in good working order. Regularly check the output of your UV system to ensure it is delivering the required energy for proper curing.

Operator training is indispensable. Your team needs to understand the nuances of UV curing. They should know how to handle UV inks safely. They need to be aware of the specific requirements for running UV jobs. Proper training leads to fewer errors and higher quality output.

Waste management is also a consideration. While UV curing reduces VOCs, spent ink and cleaning materials still need disposal. Follow environmental guidelines for handling and disposing of UV-related waste.

The flexibility of UV curing flexo printing is a major draw. It’s not just for standard labels. It’s ideal for a vast array of specialized applications. This includes high-security labels, tamper-evident labels, and labels with special finishes like spot varnishes. The ability to overprint with UV coatings adds another layer of functionality and aesthetic appeal.

In summary, UV curing flexo printing offers a compelling combination of speed, quality, and durability for label production. The shift towards LED UV technology further enhances its efficiency and environmental profile. By adhering to best practices in substrate selection, ink choice, press operation, and operator training, label printers can fully leverage the advantages of this advanced printing method. This ensures they can meet the demanding requirements of today’s market and produce exceptional labels consistently.