The print industry’s heartbeat has always been innovation, and by 2025, UV printing pulses with a new rhythm. LED curing systems aren’t just an upgrade—they’re rewriting the rules. Let’s unpack why these systems dominate labels, flexo, offset, and narrow-web printing, and how they’ve become non-negotiable for shops aiming to stay competitive.

Labels That Stick—Without the Wait

Label printers face a tightrope walk: vibrant colors demand perfect curing, but deadlines hate delays. Traditional mercury lamps once dictated the pace, requiring warm-up times that bottlenecked production. LED curing flips the script. Instant on/off capabilities slash downtime, letting presses roll straight into jobs. No more waiting for bulbs to hit optimal temperatures. For pressure-sensitive labels on pharmaceuticals or cosmetics, this means sharper metallics and whites without the risk of substrate warping. The result? Labels that pop on shelves and survive harsh environments.

Flexo’s Quiet Revolution

Flexographic printers know the pain of dot gain and registration drift. Heat from conventional UV systems expands plates and distorts fine details. LED curing sidesteps this by generating minimal heat, locking in precise dot structures. Imagine printing flexible packaging for snacks—every line of nutritional text stays crisp, even on temperature-sensitive films. Printers report fewer plate changes and less waste, thanks to stable curing that doesn’t tax materials. It’s flexo without the guesswork.

Offset’s Climate Control

Sheetfed offset thrives on consistency, but mercury lamps turned presses into saunas. Paper absorbs that heat, curling edges and disrupting feeder systems. LED’s cool operation keeps substrates flat, whether it’s business cards or luxury packaging. Printers running hybrid UV/offset setups see fewer jams and higher throughput. One Midwest shop cut its spoilage rate by 18% after switching—proof that staying cool under pressure pays off.

Narrow Web, Broad Impact

In narrow-web printing, versatility is king. LED systems deliver it by handling diverse substrates without missing a beat. Think unsupported films for medical devices or textured stocks for craft beverages. Unlike older UV tech, LEDs maintain intensity across long runs, so the 10,000th label matches the first. Hybrid ink formulations, optimized for LED wavelengths, ensure adhesion even on tricky surfaces like recycled PET.

Why Mercury Lamps Fade Out

The phase-out isn’t just about efficiency—it’s regulatory. RoHS and EPA guidelines now penalize mercury use, pushing shops toward compliant alternatives. LEDs check every box: no toxic elements, 50,000-hour lifespans (versus mercury’s 1,500), and energy use slashed by 70%. Maintenance crews breathe easier too—no more bulb replacements or hazardous waste protocols.

Inks Designed to Shine

LED curing’s rise pushed ink chemists to innovate. Modern formulations activate at specific wavelengths (365-405nm), ensuring full curing without overexposure. Low-migration inks for food packaging cure completely, eliminating risk of contaminants. For industrial applications, scratch-resistant coatings bond instantly, even on non-porous metals. Printers gain flexibility to tackle jobs they’d once decline.

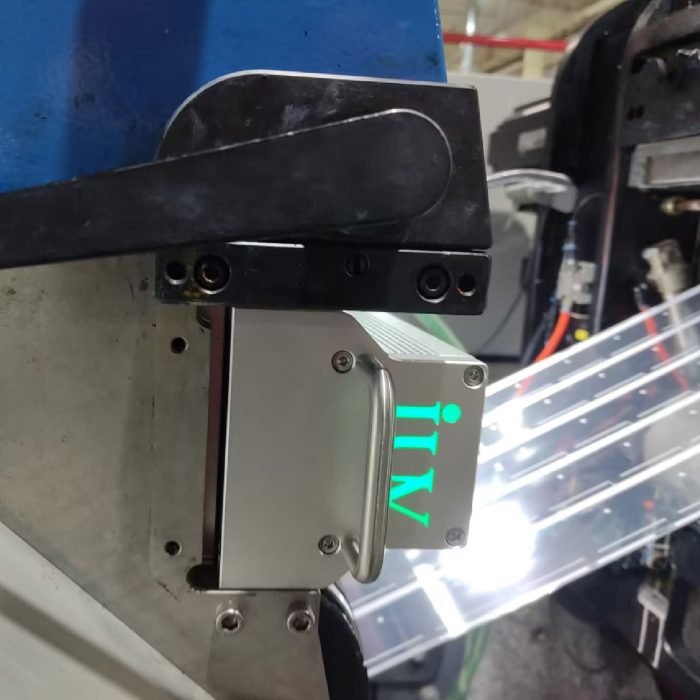

The Silent Shift in Shop Floors

Adopting LED curing isn’t a flashy overhaul. Retrofitting existing presses with LED arrays is common, minimizing downtime. Operators note the change in workflow—no warm-up rituals, no heat exhaust management. One converter described it as “switching from a gas stove to induction: faster, cleaner, and harder to burn things.”

As 2025 unfolds, shops without LED curing face a stark reality: competitors moving faster, wasting less, and winning bids they can’t touch. The question isn’t why switch—it’s how soon can you afford to. The industry’s direction is lit, and the path only brightens from here.