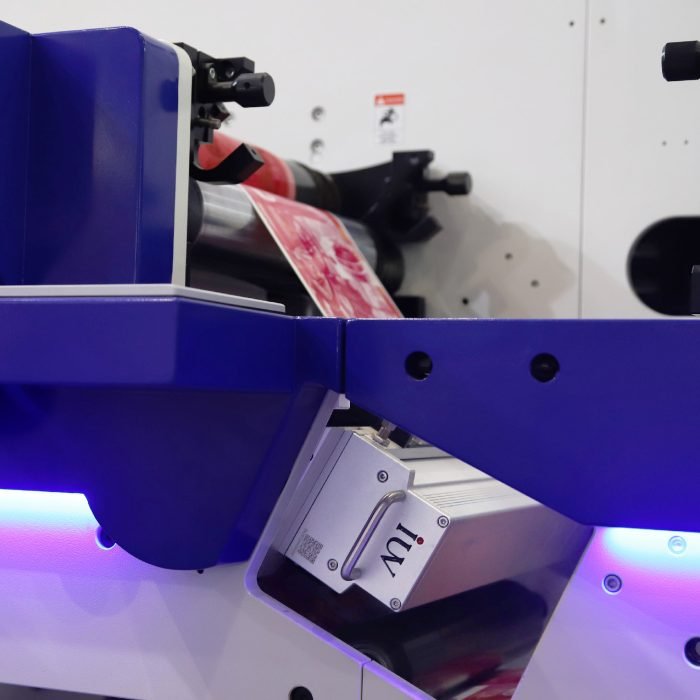

Commercial printing thrives on speed without sacrificing quality. Enter LED curing systems—game-changers reshaping how presses handle ultraviolet drying across label, flexo, offset, and narrow-web applications. Unlike traditional mercury-vapor lamps, these solid-state light sources deliver targeted energy that instantly transforms wet inks into durable prints.

Label presses gain particular advantages from LED-UV setups. The instant on/off capability eliminates mercury lamps’ warm-up delays, allowing quick job changeovers for short-run pharmaceutical labels or seasonal beverage stickers. Cold-cure technology prevents heat distortion on thin polyester films and pressure-sensitive materials. A major European label converter reported 18% faster production cycles after switching to LED, citing reduced substrate warping and immediate post-cure handling.

Flexographic operations benefit from LEDs’ spectral precision. By tuning wavelengths to match photoinitiators in water-based inks, printers achieve full curing at 50% faster line speeds compared to conventional drying tunnels. The directional nature of LED arrays minimizes energy waste—printers often see 60-70% power consumption drops. One Midwest packaging plant eliminated ozone generators previously needed for mercury lamp setups, slashing ventilation costs by 40%.

Sheetfed offset shops leverage LED curing to bypass spray powder and drying racks. Inline UV modules instantly harden coated stocks, enabling perfecting units to print both sides in single passes. A Tokyo book printer reduced make-ready waste by 23% using LED-cured varnishes that don’t require lengthy drying tests. The technology’s low heat output also prevents coated papers from curling—a persistent headache with infrared drying systems.

Narrow-web hybrid presses demonstrate LED flexibility best. Converters running combination jobs (foil stamping variable data tactile coatings) appreciate the modularity of adding cure stations between print units. A Canadian security printer integrated three LED arrays across their 20-inch web line, achieving complete curing of optically variable inks without slowing their 150 fpm run speed.

Energy efficiency metrics reveal compelling ROI. Mercury lamps operate at 25-35% efficiency; LEDs hit 85-90% electrical-to-UV conversion rates. Maintenance costs plummet since LED arrays last 15,000-20,000 hours versus 1,000-2,000 hours for traditional bulbs. California’s strict VOC regulations pushed multiple printers toward LED systems that cure without generating ozone—a side effect of mercury lamps’ broad-spectrum output.

Material compatibility continues expanding. Recent LED formulations now cure thick white inks in single passes for metalized labels, previously requiring multiple mercury lamp exposures. Screen printers adopting UV-LED hybrids report 30% faster production of automotive decals using 80µm ink deposits. The absence of infrared radiation allows curing heat-sensitive substrates like shrink sleeves and thin-gauge PET without pre-cooling.

As print buyers demand faster turnarounds and eco-conscious options, LED curing positions commercial printers to compete with digital alternatives. The technology’s silent operation (no blowers or exhaust systems) enables installations in urban areas with noise restrictions. Early adopters gain marketing edge—one Midwest printer landed a national brewery contract by demonstrating 48-hour production cycles for limited-edition cans using LED-cured metallic inks.

Transition challenges exist. Initial investments require careful ROI calculations, though utility rebates for energy-efficient equipment help offset costs. Operators need training to optimize lamp intensity for different ink formulations—under-curing causes adhesion issues while over-curing wastes power. Strategic partnerships with ink suppliers prove critical, as viscosity and pigment load affect cure depth.

The next evolution involves smart curing systems. Prototype units now adjust UV output in real-time using spectral sensors that monitor ink film thickness. Such closed-loop controls could automate energy use while guaranteeing perfect curing across variable print conditions. Another frontier combines LED with electron beam curing for hybrid systems that handle opaque metallic inks and clear coatings simultaneously.

Print facilities weighing productivity upgrades should audit current drying bottlenecks. Track how much time gets lost waiting for conventional curing—then calculate potential gains from LED’s instant capabilities. Factor in hidden savings: reduced HVAC loads, elimination of bulb disposal fees, and floor space reclaimed from drying racks. For operations running multiple shifts, the math often justifies retrofitting existing presses with UV-LED modules within 18-month payback periods.

This technology isn’t future speculation—it’s present-day reality transforming shop floors. From label converters needing faster turnaround on cannabis packaging to commercial offset houses chasing premium effects on luxury catalogs, LED curing delivers measurable competitive advantages. The question shifts from whether to adopt, to how quickly implementation can occur without disrupting live jobs.