In the fast-paced world of printing, waiting for ink to dry feels like watching paint dry – literally. LED curing systems and UV inks have become the industry’s caffeine shot, delivering instant results without the jitters. Let’s break down how this combo revolutionizes label, flexo, offset, and narrow web printing while making adhesion stronger than your morning espresso.

Label Printing Gets a Glow-Up

Sticky situations arise when printing on heat-sensitive filmic materials or metallic substrates. Traditional drying methods often warp delicate label stocks or struggle with opaque finishes. LED UV curing eliminates heat damage by using specific light wavelengths to trigger photochemical reactions in inks. The instant cure locks pigments into place on tricky surfaces like polyethylene sleeves or embossed paper – no warping, no waiting. One converter reduced label waste by 18% after switching to LED-curable UV inks for premium cosmetic packaging.

Flexo’s Speed Demon Mode

Flexographic printers running water-based inks know the pain of drying tunnels stretching halfway across the facility. LED units mounted directly on press towers zap inks solid before substrates even reach the next print station. A midwestern packaging plant crammed 40% more jobs into their production schedule by ditching solvent-based inks for UV alternatives cured with 395nm LEDs. Bonus: zero VOC emissions means you can skip the gas masks.

Offset’s Adhesion Breakthrough

Sheetfed offset operators often play chemist, tweaking ink formulations for different stocks. UV inks cured with LED arrays stick to coated papers, plastics, and even glass surfaces without primer. The secret lies in photoinitiators tuned to LED wavelengths – they create molecular bonds stronger than traditional oxidative curing. A book printer eliminated coating steps for high-gloss art portfolios by using LED-cured UV inks that bond directly to synthetic paper.

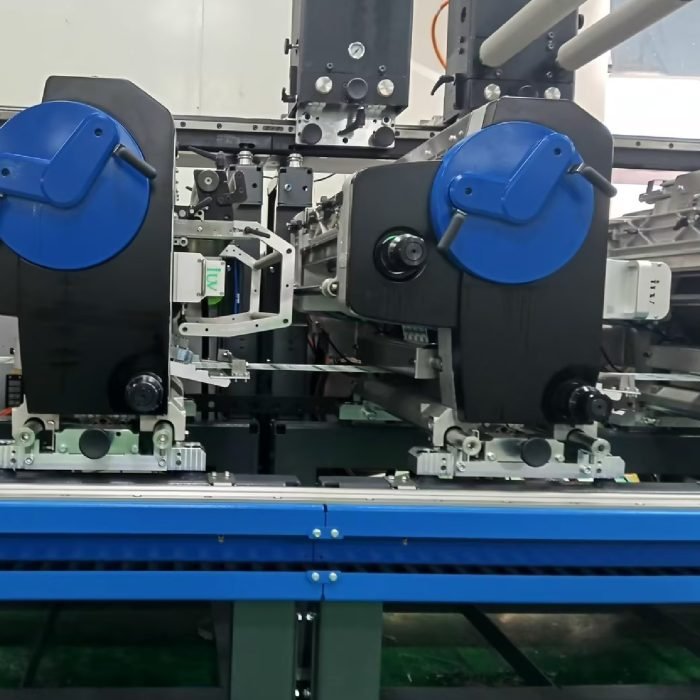

Narrow Web’s Precision Play

When printing 10mm wine labels or micro-text security features, every micron matters. LED systems provide pinpoint curing control that mercury lamps can’t match. Adjustable intensity settings prevent over-curing thin lines while ensuring complete polymerization in solid areas. A European security printer achieved 98% first-pass yield on holographic tax stamps using UV inks with LED curing – crucial when every defect means reprinting entire rolls.

The Chemistry Behind the Flash

UV inks aren’t just regular inks with extra vitamins. They contain oligomers that remain liquid until specific light wavelengths hit the photoinitiators. LED systems emit narrow-band UV light (typically 365-405nm) that activates these compounds without the infrared heat of broad-spectrum lamps. This spectral precision allows formulators to create inks that cure completely in 0.3 seconds yet remain stable in the pan for weeks.

Energy Savings That Actually Matter

Unlike mercury lamps that stay glowing during coffee breaks, LEDs only draw power when curing. A label converter slashed their energy bill by 62% after replacing 12 mercury bulbs with LED units. The kicker? LEDs maintain consistent output for 20,000 hours – no gradual intensity drop-off. Maintenance crews appreciate not handling toxic mercury vapor lamps during replacements.

The Substrate Shuffle

From crinkly BOPP films to textured recycled boards, modern printing surfaces demand adaptable curing. LED systems allow on-the-fly intensity adjustments between jobs. Run fluted polypropylene tags at 80% power, then crank to full blast for thick UV varnish on premium labels. This flexibility prevents the “overkill” effect of one-size-fits-all curing that either under-processes or fries delicate materials.

Myth-Busting the LED Transition

“But mercury lamps cure faster!” Not anymore. Latest-generation LEDs match or exceed traditional curing speeds while using less energy. “UV inks cost more.” True – until you factor in reduced waste, faster job turnover, and eliminated coating steps. One printer found their actual cost per sheet dropped 22% after switching, despite higher ink prices.

Future-Proofing Print Facilities

As sustainability mandates tighten, LED UV systems check multiple boxes: no ozone emissions, reduced energy use, easier recycling of cured substrates. They’re becoming the gateway drug for printers dipping toes into eco-friendly practices without sacrificing productivity. The tech keeps evolving – some systems now incorporate dual-wavelength LEDs to cure hybrid ink systems in single passes.

This isn’t just about faster drying times. It’s about unlocking new applications – printing on temperature-sensitive biomaterials, creating tactile effects without secondary processes, achieving metallics that don’t rub off. The shops embracing LED UV curing aren’t just keeping up; they’re printing possibilities that didn’t exist five years ago.