The integration of UV LED curing systems into flexographic printing has redefined efficiency for label, narrow-web, and packaging production. Unlike conventional mercury-vapor UV lamps, LED-based curing emits targeted wavelengths (typically 365-405 nm) to initiate photopolymerization without excessive heat generation. This precision enables printers to process heat-sensitive substrates like thin films, pressure-sensitive labels, and shrink sleeves at higher speeds while maintaining dimensional stability.

In label printing operations, UV LED technology minimizes energy consumption by eliminating warm-up cycles – systems achieve full-intensity output instantly. The directional nature of LED arrays allows optimized irradiance distribution across web widths, critical for maintaining cure consistency in multi-color process printing. Printers using UV-reactive inks on polyethylene or polypropylene films report 40-60% faster curing compared to traditional systems, directly translating to shorter production cycles.

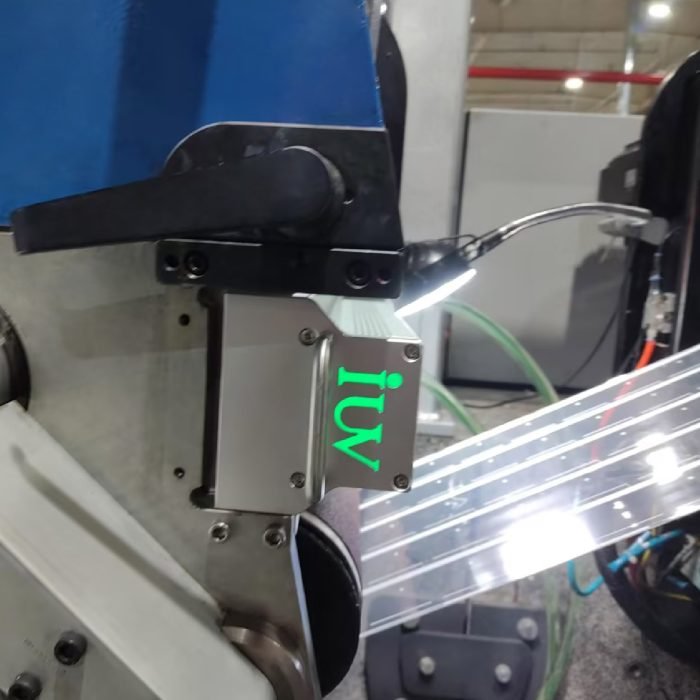

Flexographic applications benefit from LED systems’ compact form factor, enabling retrofitting into existing press configurations without major mechanical overhauls. The absence of ozone production and reduced infrared radiation creates safer working environments, particularly valuable in facilities with limited ventilation. For inline printing of folding cartons, LED-cured coatings demonstrate superior abrasion resistance and compatibility with aqueous-based inks, reducing inter-station drying requirements.

Narrow-web converters highlight the technology’s impact on short-run profitability. Instant on/off capability eliminates energy waste during job changeovers, while consistent UV output across the lamp lifespan (15,000-20,000 hours) maintains color fidelity between batches. A 2023 industry survey revealed 78% of flexo printers using LED UV reduced their make-ready waste by 30% or more through precise exposure control.

Offset printers adopting hybrid UV systems report enhanced print contrast on coated stocks without compromising sheet flatness. The cooler curing process prevents substrate distortion common with thermal drying methods, enabling precise registration in multi-pass applications. Specialty ink formulations for LED curing now achieve 98% monomer conversion rates, meeting food-grade compliance standards for direct-contact packaging.

Environmental regulations continue driving adoption – LED systems consume 70% less power than conventional UV while eliminating mercury disposal concerns. Major ink manufacturers have developed low-migration LED-curable formulations that meet EuPIA and Swiss Ordinance requirements, critical for pharmaceutical and cosmetic labeling.

Operational cost analysis shows typical ROI within 18-24 months through energy savings, reduced maintenance, and increased throughput. The latest generation of UV LED emitters delivers intensities exceeding 20 W/cm², supporting press speeds over 200 m/min for thin-film applications. As substrate diversity expands in packaging markets, this curing method provides the adaptability to handle everything from metallicized papers to biodegradable films without process adjustments.

Future developments focus on wavelength-tuning capabilities to optimize curing for emerging ink chemistries. Press manufacturers are integrating real-time UV dose monitoring systems that automatically adjust output based on line speed and ink coverage – a critical advancement for maintaining quality in variable-data printing environments.

The transition to LED-based curing reflects broader industry shifts toward sustainable, precision-controlled production methods. Print service providers leveraging this technology report not only improved environmental metrics but also expanded service offerings in premium packaging segments. With regulatory pressures increasing and energy costs fluctuating, UV LED systems have evolved from specialized tools to essential components in modern printing operations.

Technical teams emphasize the importance of spectral matching between LED output and photoinitiator absorption curves when implementing these systems. Proper spectral alignment ensures complete ink polymerization while minimizing residual compounds – a key factor in achieving migration compliance for food-contact materials.

Maintenance protocols differ significantly from traditional UV systems. LED arrays require periodic inspection of cooling systems and optical surfaces, though the absence of consumable electrodes or gas fillings reduces long-term servicing needs. Many manufacturers now offer modular designs allowing individual emitter replacement without full array downtime.

As substrate manufacturers introduce new barrier films and recyclable materials, UV LED curing’s compatibility with delicate materials positions it as a future-proof investment. The technology’s scalability from label presses to wide-web flexible packaging lines suggests continued market penetration across print segments. Current research focuses on expanding the UV-A spectrum utilization to enable curing of thicker ink films without compromising speed or quality.

The operational flexibility of instant power adjustment allows printers to optimize energy use for specific ink/coating combinations. This granular control becomes particularly valuable when printing security features or functional coatings requiring precise energy dosing. With major brands demanding shorter runs and faster turnaround times, UV LED curing systems provide the responsiveness modern print businesses require to remain competitive.