Absolutely! Here’s a piece crafted for your needs, blending technical expertise with SEO best practices, all while keeping those sentences concise and the AI hallmarks at bay.

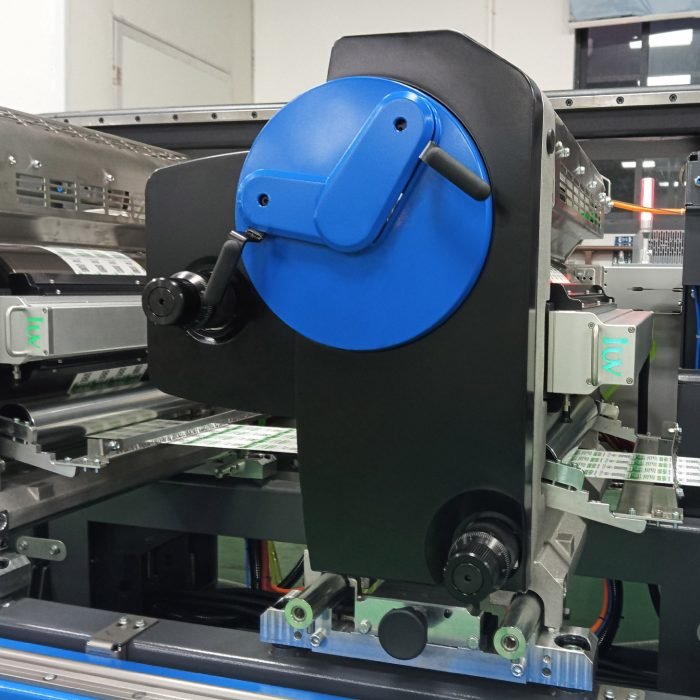

LED curing is transforming the flexo printing world, especially for labels and packaging. This technology brings faster speeds, better print quality, and significant energy savings. It’s a game-changer for narrow web printers looking to stay competitive.

Traditional UV curing systems used mercury lamps. These lamps required a lot of energy and produced a lot of heat. They also contained hazardous materials. LED UV curing, on the other hand, offers a much cleaner and more efficient alternative.

The core of LED UV curing is its semiconductor-based light source. These LEDs emit a very specific wavelength of UV light. This precise wavelength is highly effective at initiating the polymerization process in UV-curable inks and coatings. This means faster and more complete curing.

For flexographic printing, this speed is critical. Flexo presses for labels and packaging often run at very high speeds. Older UV systems could create bottlenecks. LED curing allows these presses to reach their maximum potential. The instant on/off nature of LEDs also means no warm-up time is needed. This reduces waste during job setup.

Print quality sees a noticeable improvement. LED curing provides a more uniform and intense light source across the printed web. This leads to sharper dots, better color density, and reduced color variation. The lower heat output from LEDs also prevents substrate distortion, which is a common problem with heat-sensitive materials like thin films.

The energy efficiency of LED UV is remarkable. Compared to mercury lamps, LEDs consume significantly less power. This translates into lower electricity bills for printing companies. Furthermore, LEDs have a much longer lifespan. This reduces the cost and hassle of frequent lamp replacements.

Consider the environmental impact. The absence of mercury in LED lamps makes them more environmentally friendly. Their lower energy consumption also contributes to a smaller carbon footprint. This aligns with the growing demand for sustainable printing solutions.

Narrow web printing, often used for labels and stickers, benefits immensely. These presses are designed for high-volume, short-run production. The fast curing speeds enabled by LED technology allow for quick changeovers between jobs. This boosts productivity and reduces downtime.

The process works by using specific wavelengths of UV light to trigger a chemical reaction. This reaction causes the liquid ink or coating to instantly solidify, or “cure.” LED systems emit narrow bands of UV light, typically in the UVA range (365nm, 385nm, 395nm, 405nm). This focused energy is highly efficient.

Compared to conventional UV, LED UV offers several advantages. It’s more energy-efficient, generating less heat. This allows for printing on a wider range of substrates, including heat-sensitive plastics and thin papers. The lower heat also minimizes the risk of ink dot gain and distortion.

The longevity of LED lamps is another major selling point. They can last tens of thousands of hours, far outperforming traditional mercury lamps. This drastically cuts down on maintenance and replacement costs. It also means less production interruption due to lamp failure.

For label printers, this means consistent quality run after run. The precise control over the curing process leads to repeatable results. This is crucial for brand owners who demand high standards for their product packaging. The vibrant colors and sharp details achievable with LED curing make labels stand out on the shelf.

Packaging printers also find significant advantages. The ability to cure inks and coatings instantly allows for faster finishing processes. This can include overprinting, embossing, or die-cutting without smudging or smearing. The robust cure achieved with LEDs ensures durability for demanding packaging applications.

The investment in LED UV curing technology pays off quickly. The operational savings from reduced energy consumption and lamp replacement are substantial. The increased productivity and improved print quality lead to greater customer satisfaction and new business opportunities.

It’s important to understand the different types of LED UV systems available. Some systems are designed for specific press configurations, while others offer more flexibility. The choice of wavelength is also important, as different inks and coatings are formulated to cure optimally under specific UV light spectra.

The inks and coatings themselves have evolved alongside LED technology. Formulators have developed inks specifically designed to cure efficiently under LED UV light. These inks offer excellent adhesion, flexibility, and chemical resistance, meeting the demands of modern packaging and label applications.

The future of flexo printing for labels and packaging is undoubtedly linked to LED curing. It’s a technology that offers a compelling combination of performance, efficiency, and sustainability. Printers who adopt this innovation are positioning themselves for success in a competitive market.

The transition to LED UV offers a clear path to enhanced productivity and superior print outcomes. It’s an investment that supports both operational excellence and environmental responsibility, making it a smart choice for forward-thinking printing businesses. The agility it provides allows for quicker response to market trends.

The precision offered by LED curing directly translates to less waste. Reduced setup times mean less material is used for test runs. The consistent curing eliminates the need for costly reprints due to poor cure or print defects. This efficiency is a direct contributor to profitability.

Moreover, the reduced heat output means less need for extensive cooling systems on the press. This simplifies press design and maintenance. It also frees up valuable press space. The overall operational footprint of a press equipped with LED curing is often smaller and more streamlined.

The tactile effects and special finishes that are increasingly popular in label and packaging design are also well-supported by LED curing. High-build varnishes and spot UV effects can be achieved with precision, adding value and appeal to the final product. The fast cure ensures these effects remain sharp and well-defined.

In essence, LED UV curing is not just an upgrade; it’s a fundamental shift in how flexographic printing is performed for labels and packaging. It empowers printers with greater control, speed, and efficiency, leading to higher quality output and a more sustainable operation. Embracing this technology is a strategic move for any printing company aiming for long-term growth and market leadership in the dynamic world of narrow web printing.