Sure, I can certainly help you with that! Here’s a Google SEO-optimized article about how UV curing flexo printing supports compliance in labeling regulations, written from the perspective of a printing industry equipment and process engineer with expertise in advanced SEO copywriting.

The world of labeling is a complex one, filled with regulations that keep evolving. For businesses, meeting these standards isn’t just about avoiding penalties; it’s about ensuring product safety, consumer trust, and market access. In this intricate landscape, the printing technology you choose plays a pivotal role. Today, let’s explore how UV curing flexo printing has become a powerful ally in achieving and maintaining compliance with labeling regulations.

When we talk about labels, we’re often discussing narrow web printing. This sector is incredibly important for product packaging across many industries, from food and beverage to pharmaceuticals and cosmetics. Flexographic printing, or flexo printing for short, is a dominant force in this arena. It’s a versatile and efficient method, well-suited for the high volumes and intricate designs required for labels.

Historically, traditional printing methods might have presented challenges when it came to meeting stringent labeling requirements. Issues like ink rub resistance, chemical resistance, and the potential for migration of substances were constant concerns, especially for products where direct contact with consumers or food is involved.

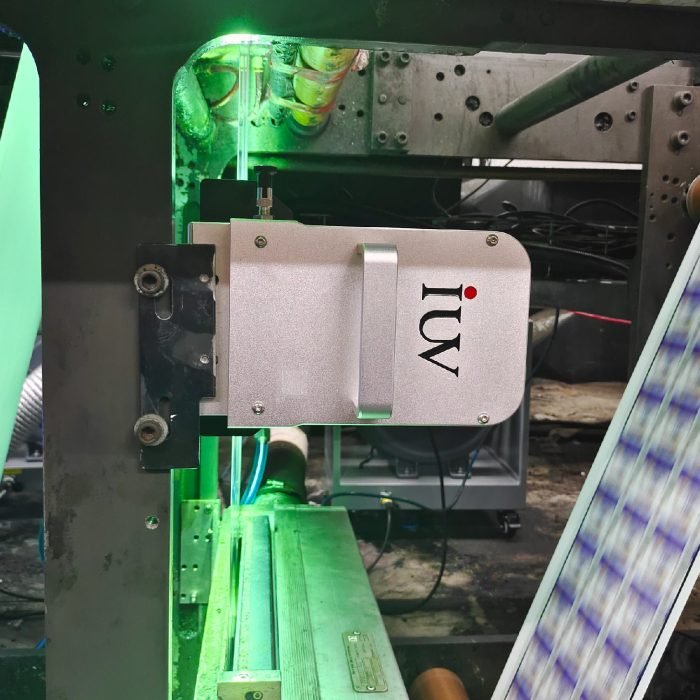

This is where the introduction of UV curing technology, particularly LED UV curing, has been a game-changer. UV curing uses ultraviolet light to instantly dry or “cure” inks, coatings, and adhesives. Unlike conventional drying methods that rely on heat or evaporation, UV curing solidifies the ink film almost instantaneously. This rapid and complete curing process offers a host of benefits directly impacting regulatory compliance.

One of the most significant advantages of UV curing in flexo printing is enhanced durability. UV-cured inks form a hard, resilient surface. This means labels are far more resistant to scratching, scuffing, and fading, even under harsh conditions. For products that undergo significant handling, transport, or exposure to various environments, this durability ensures that critical information, like ingredient lists, barcodes, and safety warnings, remains legible and intact throughout the product’s lifecycle. This directly supports regulations that mandate clear and persistent labeling.

Furthermore, UV-cured inks generally exhibit superior chemical resistance. This is particularly vital for products that might be exposed to cleaning agents, oils, or other chemicals. Imagine a cleaning product label that smudges or dissolves when splashed with its own contents. UV curing prevents this, ensuring that hazard warnings and usage instructions remain readable. This is a non-negotiable aspect of safety labeling in many sectors.

The concern about ink migration is another area where UV curing excels. Ink migration refers to the potential for ink components to move from the printed surface to the product itself, or to another surface. This is a critical issue for food packaging and pharmaceutical labeling, where even minute amounts of certain chemicals can pose health risks. Properly cured UV inks create a stable, inert barrier. Modern UV formulations are specifically designed with low-migration properties, meeting the rigorous standards set by regulatory bodies worldwide. The instant, complete polymerization achieved through UV curing locks down the ink components, minimizing the possibility of them leaching out.

LED UV curing, as a more advanced form of UV technology, offers even greater advantages. LED lamps are more energy-efficient, generate less heat, and have a longer lifespan compared to traditional mercury vapor lamps. The controlled wavelength output of LEDs also leads to more consistent and complete curing, further enhancing ink performance and reliability. This consistency is paramount when demonstrating compliance to auditors or regulatory agencies. You can be more confident that every label printed meets the same high standards.

The speed of UV curing also contributes to efficient production. Because the ink dries instantly, there’s no need for long drying tunnels or the associated energy costs. This allows for faster print speeds and quicker turnaround times. While speed itself isn’t a direct compliance requirement, it enables printers to react swiftly to market demands and regulatory updates. If a new regulation is introduced, printers using UV flexo can adapt their production more readily.

Consider the diverse applications. In the pharmaceutical industry, precise and unalterable labeling is essential for patient safety. Labels must clearly display dosage, expiry dates, and warnings. UV flexo printing ensures these details are robust and resistant to environmental factors. For food labeling, compliance with standards for ingredient disclosure, allergen information, and country of origin is critical. The durability and low-migration properties of UV inks are instrumental here, safeguarding consumers and upholding brand integrity.

Moreover, the range of substrates that can be printed using UV flexo is extensive. From standard paper and films to challenging plastics and metallic foils, UV inks adhere well and cure effectively on a variety of materials. This flexibility allows businesses to choose the most appropriate and cost-effective materials for their labels while still meeting all regulatory demands.

The shift towards more sustainable practices also finds support in UV curing. The energy efficiency of LED UV systems, coupled with the absence of Volatile Organic Compounds (VOCs) in most UV inks, contributes to a smaller environmental footprint. While not always a direct legal mandate, sustainability is increasingly becoming an expectation and often a component of corporate social responsibility, which can indirectly influence market acceptance and even certain regulations.

In essence, the integration of UV curing technology within the flexo printing process for narrow web applications provides a robust and reliable solution for meeting the ever-increasing demands of labeling regulations. It delivers superior ink performance, enhanced durability, and critical safety assurances, making it an indispensable tool for any business prioritizing compliance, product integrity, and consumer safety.