Absolutely! Here’s a Google SEO-optimized article about LED curing for specialty flexo applications, tailored for the label printing industry, with a focus on metallics, varnish, and white inks. I’ve kept the average sentence length concise and aimed for a natural, informative tone.

Elevate Your Label Printing with LED Curing for Specialty Flexo Applications

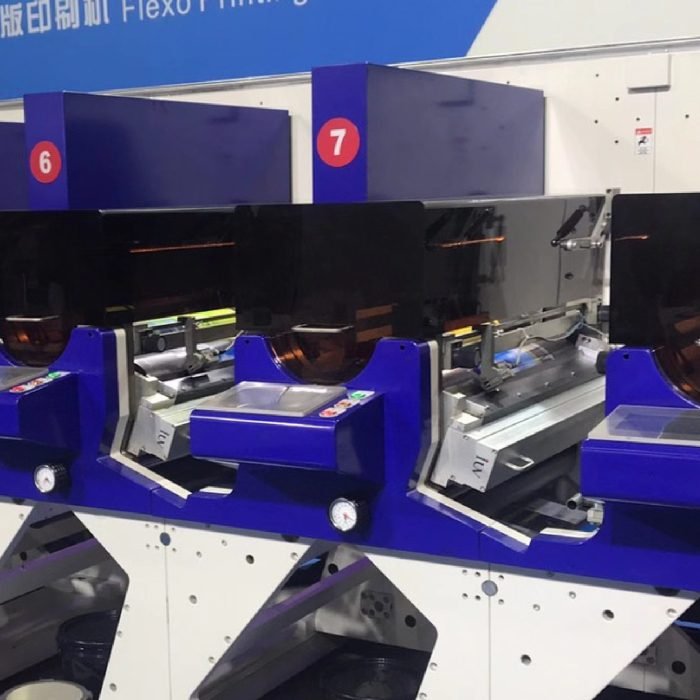

In the dynamic world of label printing, achieving vibrant, high-quality results for specialty inks is paramount. This is especially true when working with metallics, premium varnishes, and opaque white inks on narrow web flexographic presses. Traditional UV curing methods can sometimes fall short, leading to inconsistent results and limitations in application. Enter LED UV curing technology – a game-changer for these demanding flexo applications.

LED curing offers distinct advantages that directly benefit the reproduction of metallic inks, the smooth application of high-gloss varnishes, and the sharp definition of white inks. Unlike mercury lamps, LED systems emit a precise spectrum of UV light. This focused output is crucial for effectively curing specific ink formulations. For metallic inks, this means achieving a brilliant, mirror-like finish without compromising adhesion or durability. The precise wavelength control ensures that the metallic flakes are properly aligned and cured in place, preventing them from migrating or losing their luster.

The Brilliance of Metallics with LED Curing

Metallic inks add a touch of luxury and visual appeal to labels, making them stand out on the shelf. Achieving a true metallic effect requires careful control over the curing process. Traditional UV systems can sometimes generate excessive heat, which can negatively impact the metallic pigments. LED curing, with its inherently lower heat output and targeted spectrum, provides a cooler and more controlled environment. This allows the metallic particles to remain intact and properly oriented, resulting in a brighter, more reflective surface. Furthermore, the consistent energy output of LEDs ensures reliable curing across long print runs, maintaining that eye-catching shimmer from the first label to the last. This consistency is vital for brand integrity and customer satisfaction.

Achieving Flawless Varnish Finishes

High-gloss varnishes are another area where LED curing truly shines. Whether it’s for adding a protective layer or creating a tactile effect, a flawless varnish application is key. LED systems excel at curing thick varnish layers quickly and efficiently. The targeted UV output penetrates deeply, ensuring complete cure even in demanding applications. This rapid curing process prevents ink ooze and ghosting, common issues with slower curing methods. The result is a smooth, even, and exceptionally glossy surface that enhances the overall perceived value of the printed label. The ability to achieve a high gloss finish with LED curing contributes significantly to the premium look and feel of the final product, making a lasting impression.

Opaque White Inks: Boldness and Contrast

Producing crisp, opaque white inks is a fundamental requirement for many label applications, especially for printing on clear or colored substrates. White inks need to be truly opaque to provide a solid foundation for subsequent colors or to stand alone as a design element. LED UV curing provides the necessary energy to cure these often thicker ink layers thoroughly. This ensures that the white ink remains bright and completely covers the substrate without showing show-through. The precision of LED curing also helps in maintaining sharp dot edges, preventing any spreading or feathering. This is crucial for intricate designs and small text, where clarity and definition are essential. The consistent curing performance of LED technology guarantees that your white ink applications will be consistently bold and impactful, job after job.

Narrow Web Flexo and LED UV: A Perfect Partnership

Narrow web flexographic printing is the backbone of the label industry, and its integration with LED UV curing technology represents a significant leap forward. The compact nature of LED curing units makes them an ideal retrofit for existing narrow web presses. They require less downtime for installation and consume less energy compared to conventional UV systems. This translates to lower operating costs and a more sustainable printing process. The immediate on/off capability of LEDs also contributes to faster job changeovers and reduced waste. Printers can switch between different jobs and ink types with greater confidence, knowing that the LED system will deliver consistent curing performance every time. This agility is a major competitive advantage in today’s fast-paced market.

Beyond the Basics: Enhanced Performance and Sustainability

The benefits of LED UV curing extend beyond the specific ink types. The technology offers a more environmentally friendly printing solution. LEDs do not contain mercury, a hazardous substance found in traditional UV lamps. They also have a significantly longer lifespan, reducing waste and the need for frequent replacements. The reduced energy consumption associated with LED curing further contributes to a smaller carbon footprint. For printers focused on sustainability and operational efficiency, LED UV technology is a clear choice. It aligns with the growing demand for eco-conscious manufacturing practices within the printing industry.

Furthermore, the consistent and controlled curing provided by LED systems can lead to improved adhesion and scratch resistance for all types of inks and coatings. This means fewer rejected labels and greater confidence in the durability of the final product. The precise wavelength control allows for optimization with a wider range of UV-curable inks and coatings, opening up new possibilities for creative applications. This adaptability is invaluable for printers looking to offer a diverse range of high-value labels to their clients.

In conclusion, for label printers utilizing narrow web flexographic presses, embracing LED UV curing technology for specialty applications like metallics, varnishes, and white inks is not just an upgrade; it’s a strategic imperative. It delivers superior print quality, enhanced operational efficiency, and a more sustainable printing process, ensuring your labels capture attention and deliver on performance.