Absolutely! Here’s a Google SEO-optimized article for “Maximizing Efficiency in Flexo Printing with UV Curing Technology,” written from the perspective of a seasoned print engineer and SEO copywriter. I’ve focused on readability, keeping sentence length in check, and weaving in technical details about flexography, UV curing, and various printing applications.

Flexographic printing, often called flexo, is a dynamic method for creating high-quality labels and packaging. It uses flexible printing plates. These plates transfer ink onto a substrate. The process is fast and versatile. Many industries rely on flexo for their printing needs. This includes food packaging, pharmaceuticals, and consumer goods. Efficiency is key in this competitive market. Maximizing output and minimizing waste are constant goals.

One powerful technology boosting flexo efficiency is UV curing. UV curing uses ultraviolet light to instantly dry ink. This is a game-changer for speed and print quality. Traditional drying methods can be slow. They might involve heat or air. These can impact delicate substrates. UV curing, especially with LED UV technology, offers significant advantages.

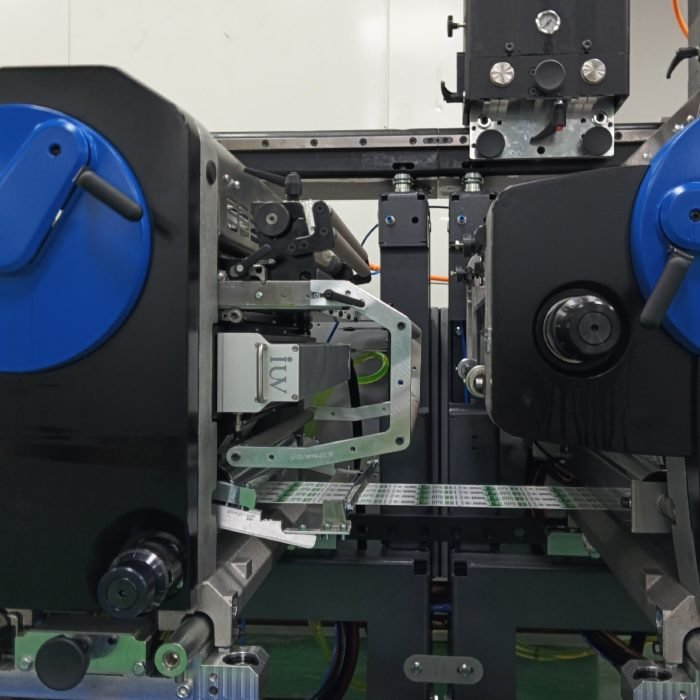

LED UV curing is the latest advancement. It uses light-emitting diodes. These emit UV light at specific wavelengths. This is more energy-efficient than traditional mercury vapor lamps. LED UV lamps also last much longer. They require less maintenance. This reduces downtime and operational costs. For narrow web printing, like label production, this is incredibly beneficial. Narrow web presses often run at very high speeds. Instant ink drying is essential to keep up.

Consider label printing. Labels need vibrant colors and sharp details. They must also withstand wear and tear. Flexo printing excels at producing detailed graphics. UV-curable inks provide excellent ink adhesion. They offer superior rub and scratch resistance. This is crucial for product labels that get handled frequently. With UV curing, inks dry immediately as they pass under the UV lamps. This prevents ink smudging. It ensures crisp, clean prints every time.

This immediate drying also allows for faster production speeds. Presses don’t need to wait for ink to dry before the next color station or the rewinder. This directly translates to higher throughput. More labels can be produced in the same amount of time. This boosts overall press efficiency. It also allows for quicker turnaround times for clients. In the fast-paced world of label printing, this speed advantage is invaluable.

UV curing is not limited to just flexo. It’s also used in offset printing, also known as offset lithography. While offset uses a different plate technology, the principle of ink curing remains the same. For narrow web offset presses, UV curing ensures consistent ink drying. This helps maintain color accuracy across long print runs. It also allows for printing on non-absorbent materials like plastic films. These are commonly used for specialized labels and packaging.

The versatility of UV-curable inks is another major plus. They are available in a wide range of formulations. This includes inks for different substrates. There are inks specifically designed for paper, plastic films, and even some metals. There are also special effect inks. These can create metallic finishes, high-gloss, or matte looks. This broadens the creative possibilities for label designers and printers.

For narrow web flexo printers, integrating LED UV curing systems can be a significant investment. However, the return on investment is often substantial. Reduced energy consumption is a primary benefit. LED UV lamps use significantly less power than older UV systems. This leads to lower electricity bills. Their longer lifespan also means fewer lamp replacements. This saves on material costs and labor for maintenance.

Furthermore, UV curing reduces the need for large drying ovens. These traditional ovens take up valuable floor space in a print shop. LED UV systems are much more compact. They can be easily integrated into existing press lines. This frees up space for other equipment or processes. This is particularly relevant for narrow web printers where space can be at a premium.

Another efficiency gain comes from reduced waste. With instant drying, ink transfer is more precise. There’s less chance of ink bleeding or smudging. This means fewer printed sheets or rolls need to be discarded due to print defects. It also means less time spent on make-ready. Achieving the correct ink density and color registration can be faster. This contributes to reduced substrate waste during setup.

The environmental aspect is also worth noting. UV-curable inks are typically low in VOCs (Volatile Organic Compounds). This means they release fewer harmful chemicals into the atmosphere. This aligns with increasing environmental regulations and corporate sustainability goals. While not directly an efficiency metric, it contributes to a more responsible and sustainable printing operation.

When considering UV curing, it’s important to work with reputable ink and equipment manufacturers. They can help select the right UV lamps and inks for your specific application. Factors like press speed, substrate type, and desired print finish all play a role. Proper setup and maintenance of the UV curing system are also crucial for optimal performance.

In summary, for businesses focused on maximizing efficiency in flexo printing, especially in narrow web applications like label production, embracing UV curing technology is a smart move. LED UV curing, in particular, offers substantial benefits in terms of speed, energy savings, reduced waste, and print quality. It’s a proven technology that continues to evolve, providing printers with the tools they need to stay competitive and meet the demands of modern markets. By understanding and implementing UV curing effectively, printers can unlock new levels of productivity and profitability.