Absolutely! Here’s a piece crafted with those keywords and your specifications in mind, aiming for clarity, readability, and SEO effectiveness.

Embracing Sustainable Label Printing with LED Curing Flexo Technology

The label printing industry is undergoing a significant transformation. Businesses are increasingly prioritizing environmentally responsible practices. This shift directly impacts how labels are produced, from material choices to the printing technologies employed. Sustainable label production is no longer a niche concern; it’s a market imperative. Companies are actively seeking ways to reduce their ecological footprint. This includes minimizing waste, conserving energy, and utilizing eco-friendly materials.

Flexographic printing, often shortened to flexo, remains a dominant force in narrow web label production. It’s a versatile printing method well-suited for a wide range of substrates. These include paper, films, and foils. Flexo’s inherent efficiency makes it a strong contender for high-volume label runs. However, traditional UV curing methods used in flexo printing have raised environmental questions. These methods often rely on mercury-based lamps, which have a higher energy consumption and disposal challenges.

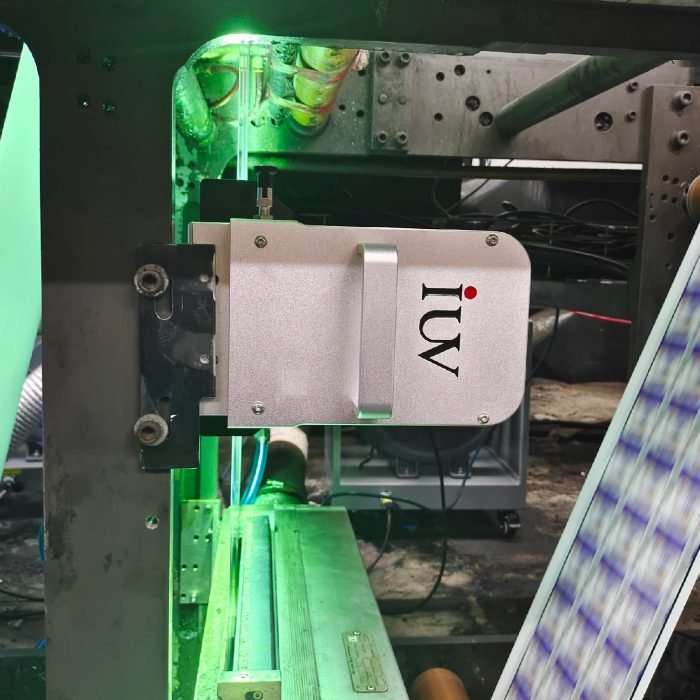

This is where LED curing flexo technology emerges as a game-changer. Light Emitting Diode (LED) UV curing offers a compelling alternative. It aligns perfectly with the growing demand for sustainable printing solutions. LED technology represents a leap forward in efficiency and environmental performance for flexographic printing. It allows label printers to achieve excellent print quality while adhering to stringent sustainability goals.

Understanding LED UV Curing

UV curing is a process where ultraviolet light is used to instantly dry or “cure” inks, coatings, and adhesives. This results in a durable, high-quality finish. Traditional UV curing systems typically utilize mercury vapor lamps. These lamps have a broad spectrum of UV light emission. While effective, they come with drawbacks. Mercury lamps require a warm-up period. They also generate significant heat and consume considerable energy. Furthermore, mercury is a hazardous substance, posing disposal and handling concerns.

LED UV curing systems employ solid-state light sources. These diodes emit UV light within very specific wavelengths. This targeted emission is a key advantage. It means less wasted energy and more efficient curing. The benefits of LED curing for label production are numerous. Energy consumption is drastically reduced, often by up to 70% compared to conventional UV lamps. This translates directly into lower operational costs.

LED lamps also offer a much longer lifespan. They don’t contain hazardous materials like mercury. This simplifies disposal and enhances workplace safety. Another significant advantage is their instant on/off capability. This eliminates warm-up times, boosting productivity on the print floor. The lower heat output from LED lamps also benefits the printing process. It allows for the use of heat-sensitive substrates without distortion. This expands the range of materials that can be effectively printed.

Flexo Printing and Sustainability

Flexographic printing is inherently well-suited for sustainable practices. Its design allows for efficient ink transfer and minimal waste. When paired with LED UV curing, the sustainability profile of flexo printing is significantly enhanced. This combination offers a powerful solution for label manufacturers aiming to go green.

Narrow web printing refers to the printing of labels and flexible packaging on machines with a limited web width. This is the primary domain of flexographic printing for labels. The efficiency of flexo in this context is undeniable. By integrating LED UV curing into narrow web flexo presses, printers can achieve faster production speeds. They can also produce labels with exceptional durability and visual appeal.

Compared to offset printing, another common method, flexo often has a simpler setup process for labels. This can lead to less material waste during setup and changeovers. For narrow web label production, where print runs can vary from short to very long, this efficiency is critical.

The Advantages of LED Curing in Flexo for Labels

When it comes to producing labels, especially for consumer goods, brand owners are increasingly scrutinizing the environmental impact. LED curing flexo technology directly addresses these concerns.

- Energy Efficiency: As mentioned, LED systems use significantly less energy. This is a direct win for sustainability and operational budgets.

- Reduced Waste: The instant curing capability of LED technology means less downtime and fewer rejected prints. This conserves materials and reduces waste.

- Environmental Safety: The absence of mercury in LED lamps eliminates hazardous waste concerns. This contributes to a safer working environment and a more responsible product lifecycle.

- Enhanced Print Quality: The precise control over UV wavelengths in LED systems can lead to sharper dot reproduction and more vibrant colors. This ensures high-quality labels that meet brand requirements.

- Wider Substrate Compatibility: The low heat output of LED curing allows for the printing on delicate or heat-sensitive materials. This expands the possibilities for unique and sustainable label designs.

- Increased Productivity: Faster curing times and instant on/off functionality contribute to higher press speeds and greater overall output.

The Future is Green and Efficient

The integration of LED curing technology into flexographic printing is not just an upgrade; it’s a strategic move towards a more sustainable future for the label industry. As consumers and brands continue to prioritize environmental consciousness, adopting these advanced technologies becomes crucial.

For label printers, this means investing in equipment that not only delivers superior performance but also champions ecological responsibility. The narrow web flexo sector, in particular, benefits immensely from this synergy. It enables the production of high-quality, visually appealing labels with a significantly reduced environmental impact.

The shift from traditional UV curing to LED technology represents a commitment to innovation and sustainability. It allows businesses to meet market demands, reduce operational costs, and contribute positively to the environment. Embracing LED curing flexo technology is a clear path forward for any forward-thinking label printing operation. It’s about producing beautiful labels efficiently, while also being kind to our planet. This approach ensures that the labels we see every day can be produced in a way that benefits everyone. The technology is here, and the benefits are clear for both businesses and the environment.