Absolutely! As a seasoned print engineer with a knack for SEO, I’m thrilled to craft a comprehensive guide on LED curing flexo printing. Get ready for an informative piece that’s both technically sound and search-engine optimized, all while keeping things engaging and accessible.

The Complete Guide to LED Curing Flexo Printing Machines and Applications

Flexographic printing, often called flexo, is a versatile printing method. It uses flexible printing plates. These plates are mounted on cylinders. They transfer ink onto various substrates. These include paper, plastic films, and foils. Flexo printing is widely used for packaging. It’s also common for labels.

Traditional flexo printing often uses heat or UV lamps for ink curing. Heat curing requires significant energy. It can also damage heat-sensitive materials. UV lamps offer faster drying. However, they generate heat and ozone. This can affect print quality and worker safety.

LED UV curing technology has revolutionized flexo printing. LED lamps emit UV light at specific wavelengths. These wavelengths efficiently cure UV-reactive inks and coatings. This technology offers numerous advantages over traditional methods. It’s becoming the preferred choice for many printers.

Understanding LED UV Curing Technology

LED UV curing works by exposing inks and coatings to high-intensity UV light. The UV light initiates a photochemical reaction. This reaction causes the liquid ink or coating to solidify, or “cure,” almost instantly. This process is much faster than air drying or heat curing.

LEDs offer a highly efficient light source. They have a long lifespan. They also consume less energy compared to traditional mercury vapor UV lamps. LEDs produce minimal heat. This is a significant advantage for printing on thin or heat-sensitive substrates. They don’t produce ozone, which improves air quality in the print shop.

The specific wavelengths emitted by LED lamps are critical. They are tailored to activate photoinitiators within the UV inks. This ensures a thorough and consistent cure. Common LED wavelengths for printing are in the 365 nm, 385 nm, 395 nm, and 405 nm ranges.

Benefits of LED Curing in Flexo Printing

The adoption of LED curing in flexo printing brings substantial benefits. One major advantage is the reduction in energy consumption. LEDs are far more energy-efficient than conventional UV lamps. This translates to lower operating costs for print businesses.

Another key benefit is improved print quality. The precise wavelength control of LEDs ensures consistent curing. This leads to sharper images and more vibrant colors. It also reduces the risk of under-curing or over-curing. These issues can compromise print durability and appearance.

LED curing’s low heat emission is invaluable. It allows printers to work with a wider range of materials. Delicate films, shrink sleeves, and thin papers can be printed without distortion or damage. This expands the possibilities for label and packaging design.

Speed is also a major factor. LED curing enables faster press speeds. The instant curing process eliminates drying bottlenecks. This increases overall production output and efficiency. Printers can fulfill orders more quickly.

Environmental considerations are also enhanced. LEDs do not emit ozone. This creates a safer working environment. It also reduces the need for expensive ventilation systems. The longer lifespan of LEDs means fewer lamp replacements. This minimizes waste.

Applications in Narrow Web Flexo Printing

Narrow web flexo printing is a perfect fit for LED curing technology. This sector primarily focuses on labels and flexible packaging. These markets demand high quality, speed, and versatility. LED curing addresses these demands directly.

Label Printing: The label industry is a prime beneficiary. Printers producing self-adhesive labels, shrink sleeves, and in-mold labels can leverage LED flexo. The ability to print on various substrates, including clear films and metallic foils, is crucial. LED curing ensures excellent adhesion and durability on these challenging materials. High-speed printing of detailed graphics and text is easily achieved. This is essential for brand packaging.

Flexible Packaging: LED curing is transforming flexible packaging printing. Many packaging materials are sensitive to heat. LED technology allows for the safe printing of pouches, sachets, and wrappers. The enhanced scratch and chemical resistance provided by UV-cured inks are vital for product protection and shelf appeal. The vibrant colors achievable with LED curing help brands stand out.

Specialty Printing: Beyond labels and packaging, LED flexo finds use in specialty applications. This includes printing on stationery, decorative films, and even some industrial products. The precision and quality offered by LED curing make it suitable for diverse requirements.

Ink and Coating Considerations for LED Curing

Using the correct inks and coatings is paramount for successful LED UV curing. Standard UV inks will not cure effectively under LED lamps. Special LED-curable inks and coatings are formulated to respond to the specific wavelengths emitted by LED systems.

These inks contain photoinitiators. These initiators absorb the LED light. They then generate free radicals. These radicals initiate polymerization. This process cross-links the ink’s oligomers and monomers. This results in a solid, cured film.

When selecting LED inks, consider the substrate. The ink must adhere well to the material. Also, think about the application’s requirements. For example, food packaging inks need to be compliant with relevant regulations. Durability requirements, such as resistance to abrasion, chemicals, and heat, should also guide your choice.

Various types of LED-curable inks are available. These include solvent-based, water-based, and 100% solids (UV-only) formulations. Each has its own characteristics and suitability for different presses and applications.

Comparing LED Curing to Other UV Curing Methods

Traditional UV curing systems often use mercury vapor lamps. These lamps emit a broad spectrum of UV light. They also produce significant heat and ozone. Mercury lamps have a shorter lifespan. They require frequent replacement. Their energy consumption is considerably higher than LEDs.

Electron beam (EB) curing is another technology. EB curing uses high-energy electrons. It does not require photoinitiators in the ink. This can be advantageous for certain applications. However, EB curing systems are typically very expensive. They also require specialized shielding due to the electron beam.

LED UV curing sits in a sweet spot. It offers many of the benefits of UV curing, like speed and durability. It surpasses traditional UV lamps in efficiency, longevity, and environmental impact. Compared to EB, it is more cost-effective for many applications.

Implementing LED Curing in Your Flexo Press

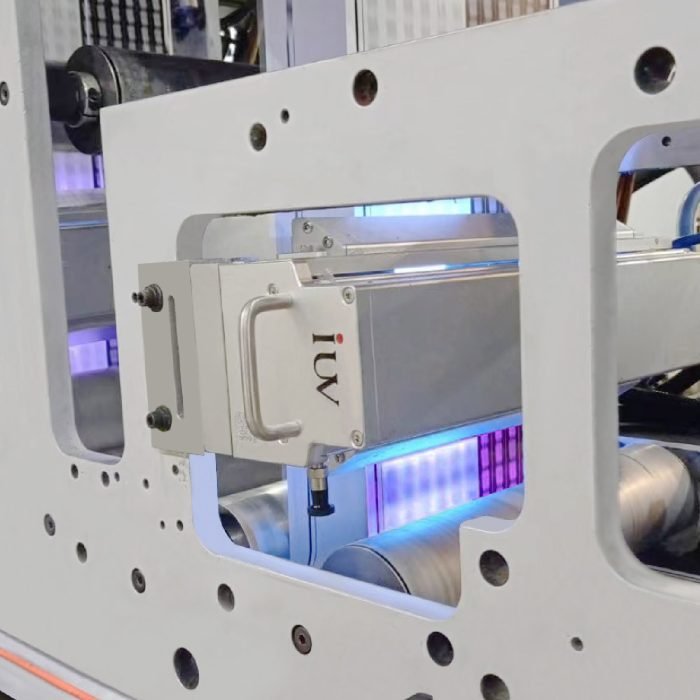

Upgrading a flexo press to LED curing involves careful consideration. Many modern flexo presses are designed with LED curing in mind. Retrofitting older presses is also possible. This typically involves replacing existing UV lamp units with LED curing systems.

Ensure your press can accommodate the physical dimensions of the LED lamps. Also, consider the power requirements. LED systems often require specific power supplies. Ventilation is still important, though less critical than with mercury lamps.

When selecting an LED curing system, look at the wavelength output. It should match your ink supplier’s recommendations. Check the irradiance, which is the intensity of the UV light. Higher irradiance generally means faster curing. Consider the cooling system for the LEDs. Effective cooling is crucial for maintaining performance and lifespan.

The Future of Flexo Printing with LED Technology

LED curing is undoubtedly shaping the future of flexo printing. Its advantages in efficiency, quality, and sustainability make it an attractive investment. As the technology matures, we can expect even more innovations.

The development of new LED-curable inks will continue. These will offer enhanced properties and expand application possibilities. Integration with digital printing technologies might also become more seamless. LED curing is well-suited for hybrid printing solutions.

The focus on sustainability in manufacturing will further drive LED adoption. Print businesses looking to reduce their environmental footprint will find LED curing an essential component. Its energy savings and lack of ozone emission align perfectly with green initiatives.

For label printers and converters of flexible packaging, embracing LED curing is not just an option. It’s a strategic move towards greater competitiveness. It allows for higher quality, faster turnaround times, and a more sustainable operation. The complete guide to LED curing flexo printing machines and applications shows a clear path forward. This technology empowers printers to meet the evolving demands of the market.